System Sensor Duct Detector Manual: A Comprehensive Guide

Welcome! This manual provides a complete overview of System Sensor duct detectors. It offers guidance for optimizing your product’s capabilities‚ ensuring proper installation and maintenance; Copies are available at www.systemsensor.com. Refer to NFPA standards 72 and 90A for detailed information‚ and local fire regulations.

System Sensor duct detectors are vital components of a comprehensive fire safety system‚ designed to sample air moving through HVAC ductwork. These detectors identify smoke particles present in the airflow‚ providing early warning of potential fires within the building’s ventilation system. Unlike standard smoke detectors‚ duct detectors are specifically engineered for the unique environment of air ducts‚ accounting for airflow and potential contaminants. Their purpose is not to replace open-area smoke detectors but to supplement them‚ offering an added layer of protection by detecting smoke before it circulates throughout the building. They play a crucial role in preventing the spread of smoke and fire‚ allowing for prompt response and evacuation. Properly installed and maintained duct detectors are essential for life safety and property protection. They can activate alarms‚ shut down HVAC systems to prevent smoke circulation‚ and alert building occupants. Before installing or using any System Sensor duct detector‚ consult the user manual for complete instructions and safety guidelines. System Sensor offers a range of duct detectors designed to meet different needs and specifications‚ and it’s important to select the right model for your application.

Understanding the Manual’s Purpose and Scope

This manual serves as a comprehensive guide for understanding‚ installing‚ operating‚ and maintaining System Sensor duct smoke detectors. Its primary purpose is to equip users with the knowledge necessary to ensure these detectors function effectively and reliably. The manual covers a wide range of topics‚ including installation procedures‚ wiring diagrams‚ electrical specifications‚ maintenance protocols‚ and troubleshooting tips. It also addresses the proper application of smoke detectors in duct systems‚ compliance with NFPA standards and local fire regulations‚ and the use of accessories and optional features. This manual is intended for use by qualified technicians and personnel responsible for the installation‚ maintenance‚ and inspection of fire protection systems. While it provides detailed instructions‚ it is not a substitute for professional training and experience. The scope of this manual is limited to System Sensor duct smoke detectors and their associated components. It does not cover other types of fire detection equipment or systems; Users should always refer to the specific product documentation for the model of duct detector they are using. The manual aims to provide clear‚ concise‚ and accurate information to help users maximize the performance and longevity of their System Sensor duct detectors.

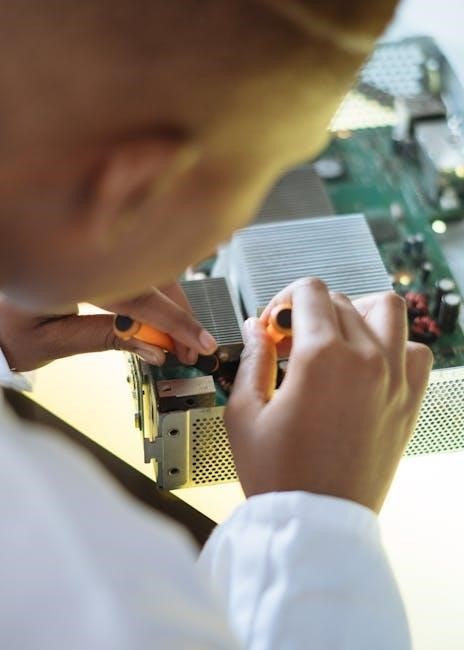

Installation Instructions for System Sensor Duct Detectors

Proper installation is crucial for the effective operation of System Sensor duct detectors. Before beginning‚ thoroughly read the System Sensor guide for proper use of smoke detectors in duct applications. Ensure compliance with all applicable NFPA standards and local fire regulations. Select a suitable mounting location‚ considering accessibility for maintenance and testing. The detector should be installed in a straight section of duct‚ away from bends or obstructions that may affect airflow. Use the provided mounting template to mark the hole locations. Securely mount the detector to the duct using appropriate hardware. Ensure the sampling tubes are properly installed and aligned with the airflow direction. The exhaust tube should point downstream. Connect the wiring according to the wiring diagrams provided in this manual. Verify that all connections are secure and properly insulated. After installation‚ perform a thorough test to ensure the detector is functioning correctly. This includes verifying the alarm signal is received by the fire alarm control panel. Document the installation date and detector location for future reference. Consult the specific detector head installation manual for detailed electrical specifications. Always prioritize safety and follow all applicable codes and regulations during installation.

Wiring Diagrams and Electrical Specifications

Understanding the wiring and electrical specifications is essential for proper installation and operation of System Sensor duct detectors. Refer to the specific wiring diagrams included in this manual for your particular detector model. These diagrams illustrate the correct connections for power‚ alarm‚ and any auxiliary devices. Ensure that all wiring complies with applicable electrical codes and regulations. Use the appropriate wire gauge and insulation for the voltage and current requirements of the detector. Pay close attention to polarity when connecting power wires. Incorrect polarity can damage the detector. The electrical specifications for each detector model are provided in this manual. These specifications include the operating voltage range‚ current consumption‚ and alarm contact ratings. Verify that the power supply used meets the detector’s voltage and current requirements. When connecting to a fire alarm control panel‚ ensure compatibility and proper configuration. Follow the control panel manufacturer’s instructions for wiring and programming. Use shielded cable for signal wiring to minimize interference. Ground the detector according to the manufacturer’s recommendations. Test the wiring after installation to ensure continuity and proper operation. Consult a qualified electrician if you have any questions or concerns about the wiring or electrical specifications.

Maintenance and Testing Procedures

Regular maintenance and testing are crucial for ensuring the reliable operation of System Sensor duct detectors. These procedures help identify potential problems early and prevent false alarms. A visual inspection should be performed at least quarterly to check for any signs of damage‚ dirt‚ or obstructions. Clean the detector as needed using a soft cloth or vacuum cleaner. Do not use harsh chemicals or solvents. Functional testing should be conducted at least semi-annually to verify that the detector is responding to smoke. Use a listed smoke detector tester to introduce simulated smoke into the detector chamber; Observe the detector’s response and ensure that the alarm is activated. The test/reset button can be used for speed-up testing mode. If the detector fails to respond to the test‚ troubleshoot the wiring and connections. If the problem persists‚ replace the detector. Leakage checks should be performed at least every 12 months‚ make sure system operate properly. Keep records of all maintenance and testing activities‚ including the date‚ time‚ and results; Refer to the manufacturer’s instructions for specific maintenance and testing procedures. These procedures are devised to assist maintenance personnel. Follow NFPA standards and local fire regulations for maintenance and testing requirements.

Troubleshooting Common Issues

When troubleshooting System Sensor duct detectors‚ systematically address potential problems to restore functionality. False alarms are a common issue; begin by verifying the detector’s cleanliness and environment. Dust‚ debris‚ or high humidity can trigger false alarms. Ensure the sampling tubes are free from obstructions and properly installed. If false alarms persist‚ adjust the detector’s sensitivity settings‚ if applicable. A lack of alarm activation during testing indicates a more serious problem. Check the wiring connections to ensure they are secure and correctly wired according to the diagrams. Verify the power supply voltage to the detector. If the power supply is adequate‚ test the detector’s functionality using the test/reset button. If the detector still fails to activate‚ replace the sensor head‚ as it may be faulty. Communication problems with the fire alarm control panel can also occur. Inspect the wiring between the detector and the panel for any damage or loose connections. Consult the panel’s manual for troubleshooting steps. Check the detector’s compatibility with the panel. Always refer to the System Sensor manual for specific troubleshooting steps and guidance. If problems persists‚ contact System Sensor’s technical support for assistance.

Proper Use of Smoke Detectors in Duct Applications

Proper use of smoke detectors in duct applications is critical for early fire detection and effective smoke management. System Sensor provides comprehensive guidelines for optimal detector placement within HVAC systems. Detectors should be installed in locations where airflow is consistent and representative of the entire duct system. Avoid installing detectors near sharp bends‚ dampers‚ or other obstructions that can disrupt airflow. Follow the manufacturer’s recommendations for spacing between detectors‚ considering duct size and airflow velocity. Regularly inspect and maintain detectors to ensure they are free from dust‚ debris‚ and other contaminants. Clean the sampling tubes and sensor chamber periodically to prevent false alarms and ensure accurate detection. Test the detectors regularly to verify their functionality. Use the test/reset button or apply simulated smoke to the sampling tubes. Document all inspections‚ maintenance‚ and testing activities. Refer to System Sensor’s application guide for duct smoke detectors for detailed information on detector spacing‚ placement‚ zoning‚ and wiring. Ensure compliance with local fire codes and regulations. Proper use of smoke detectors in duct applications enhances fire safety by providing early warning and enabling timely response measures.

NFPA Standards and Local Fire Regulations Compliance

Compliance with NFPA standards and local fire regulations is crucial for ensuring the effectiveness and legality of System Sensor duct detector installations. NFPA 72‚ the National Fire Alarm and Signaling Code‚ provides comprehensive requirements for fire detection and alarm systems‚ including duct smoke detectors. NFPA 90A‚ the Standard for the Installation of Air-Conditioning and Ventilating Systems‚ addresses the proper installation and use of duct detectors in HVAC systems. Adherence to these standards ensures that duct detectors are correctly installed‚ maintained‚ and tested. Local fire regulations may impose additional requirements or restrictions on duct detector installations. Consult with local fire authorities to understand specific requirements in your jurisdiction. Ensure that all installations are performed by qualified personnel with appropriate training and certifications. Maintain accurate records of all inspections‚ testing‚ and maintenance activities to demonstrate compliance with applicable standards and regulations. Regularly review and update your knowledge of NFPA standards and local fire regulations to stay informed of any changes or updates. Failure to comply with these requirements can result in fines‚ penalties‚ and potential liability in the event of a fire. Prioritize safety and ensure full compliance with all applicable codes and regulations.

Accessories and Optional Features

System Sensor duct detectors offer a range of accessories and optional features that enhance their functionality and adaptability to specific application requirements. Accessories can expand the versatility of the InnovairFlex line‚ including notification and test capabilities. Remote test stations allow for convenient testing of the detector from a distance‚ simplifying maintenance procedures. Relay modules provide additional control outputs for triggering auxiliary devices such as dampers or fans. Sounder bases offer local audible annunciation of alarm conditions. Filter kits protect the sensor from dust and debris‚ extending its lifespan and maintaining accuracy. Optional features include isolated sensor covers‚ improving false alarm immunity and simplifying maintenance. Some models offer adjustable sensitivity settings to optimize performance in different environments. Communication modules enable integration with building automation systems for remote monitoring and control. Explosion-proof housings are available for hazardous locations. A plug-in sensor head simplifies installation‚ testing‚ and maintenance. An improved cover design isolates the sensor. Consider the specific needs of your application when selecting accessories and optional features. Consulting with a qualified fire protection professional can help ensure that you choose the right options for your system. These additions provide enhanced control‚ monitoring‚ and protection capabilities.

Where to Find Additional Resources and Support

For comprehensive support and further information regarding System Sensor duct detectors‚ several resources are available to assist users. The primary source for documentation is the System Sensor website‚ www.systemsensor.com‚ where you can find product manuals‚ data sheets‚ application guides‚ and technical bulletins. The website also offers a document-on-demand service via fax at 800/736-7672. NFPA Standards 72 and 90A provide detailed information on fire alarm systems and air conditioning and ventilation systems‚ respectively. Local fire regulations should always be consulted for specific requirements in your area. System Sensor’s customer support team can be reached by phone or email for technical assistance and troubleshooting. Authorized distributors and dealers can provide product selection guidance and local support. Online forums and communities may offer peer-to-peer assistance and discussions on installation‚ maintenance‚ and troubleshooting. Before contacting support‚ gather the model number‚ serial number‚ and any relevant details about the issue you are experiencing. Reviewing the troubleshooting section of this manual and the online resources can often resolve common problems quickly. Consider consulting with a qualified fire protection professional for complex issues or system design questions. Remember to always prioritize safety and follow all applicable codes and regulations.

Warranty Information and Contact Details

System Sensor warrants its air duct smoke detectors against defects in materials and workmanship under normal use and service for a period specified in the product documentation. The warranty period typically begins from the date of manufacture or purchase‚ depending on the specific product and terms. This warranty is extended only to the original purchaser and is not transferable. System Sensor’s obligation under this warranty is limited to the repair or replacement‚ at its option‚ of any defective product. To obtain warranty service‚ contact System Sensor’s customer support team to request a Return Merchandise Authorization (RMA) number. Return the defective product‚ along with proof of purchase and a detailed description of the issue‚ to the address provided by customer support. This warranty does not cover damage resulting from misuse‚ neglect‚ accident‚ improper installation‚ or unauthorized modification. System Sensor shall not be liable for any incidental or consequential damages arising from the use or inability to use the product; For specific warranty details and exclusions‚ refer to the complete warranty statement included with the product or available on the System Sensor website. Contact System Sensor customer support at the phone number or email address listed on their website for further assistance or to initiate a warranty claim. Always have the product model number and serial number available when contacting support.